How to Prevent Slippery Floors After Disinfecting: Custodian Safety Guide

When Clean Turns Dangerous

You've just finished disinfecting the lobby floor. It's spotless. Germ-free. But within minutes, someone's shoes are sliding across the surface like they're on ice.

This scenario plays out daily in facilities nationwide. Custodians disinfect properly, follow protocols, yet floors turn treacherous. It's not about cutting corners—it's about chemistry working against you.

The numbers tell a sobering story: according to the U.S. Bureau of Labor Statistics, slips, trips, and falls cause over 25% of all workplace injuries. Custodial staff face even higher risks, constantly working on wet surfaces while others walk through. Understanding slip and fall prevention isn't just about compliance—it's about protecting your team.

A 2020 Journal of Safety Research review found that improper detergent and disinfectant use can reduce floor friction by up to 40%, depending on chemical formulation and surface type—proving that even compliant cleaning practices can inadvertently create slip hazards.

Here's the reality: most post-disinfection slip hazards stem from three culprits—residue you can't see, products applied incorrectly, or chemicals that don't match your floor type. Fix these workplace slip hazards, and you eliminate the problem at its source.

Why Floors Get Slippery After Mopping: The Real Culprits

When floors feel slippery after cleaning, people assume it's still wet. Usually, it's not. It's what the disinfectant left behind. Understanding why floors are slippery after mopping helps you prevent the problem before it starts.

Invisible Films That Kill Traction

Quaternary ammonium compounds (quats)—found in most commercial disinfectants—are excellent at killing germs. They're also excellent at forming microscopic films that reduce friction. This is one of the primary causes of slippery floors in commercial facilities.

A 2023 study on healthcare flooring friction found that the coefficient of friction was strongly influenced by contaminant conditions, with cleaning product residues significantly reducing floor traction. The research confirmed that floor residue buildup varies wildly based on application method, and incomplete removal creates persistent coating problems that affect safety.

The Dilution Mistake Nobody Talks About

Here's what happens in real facilities: a custodian grabs the disinfectant bottle, pours some into the bucket, adds water, and mops. No measuring. No reference to dilution charts. The result? Concentrated disinfectant that leaves heavy residue and takes forever to dry. Understanding proper dilution ratios for cleaning products is essential for preventing slippery residue on floors.

Manufacturers design these products to work at specific ratios—often 1:256 or 1:128. Use it full-strength or even double-strength, and you're essentially painting your floors with a slip agent.

When Your Floor Finish Fights Your Disinfectant

VCT floors with wax coatings, sealed concrete, and laminate with protective layers—all these finishes can chemically react with certain disinfectants. The result looks fine, but it feels like you're walking on cooking oil. This floor finish compatibility issue is one of the most overlooked causes of slippery commercial floors.

This happens most when facilities switch disinfectant brands without considering compatibility. Different chemical bases (quats vs. peroxides vs. hypochlorous acid) interact differently with floor treatments.

Humidity: The Hidden Enemy

Ever notice floors stay slippery longer on humid days? Industry experts know that high humidity dramatically slows evaporation rates—floor cleaning products that normally dry in 30 minutes can take three or more hours in humid conditions. In high-humidity environments, the air is saturated with moisture, preventing water in cleaning solutions from evaporating. This creates extended slip hazard windows where floors remain dangerously slippery long after they appear dry.

The Footprint Effect

Walk across a freshly mopped floor before it fully dries, and you're not just tracking dirt—you're compressing wet residue into the surface texture. These compressed films harden into smooth patches that are nearly impossible to see but devastatingly easy to slip on.

This is why proper signage is critical. Rubbermaid Caution Wet Floor Signs should be deployed before cleaning begins, not after someone complains. These highly visible safety signs alert occupants to stay off floors during and after disinfection, giving surfaces adequate time to dry completely. For facilities needing multiple signs or specialized safety messaging, explore the full range of safety signs to ensure every high-traffic area is properly marked during cleaning operations.

Floor-Specific Strategies: What Works for Each Surface

Not all floors are created equal. What works on ceramic tile can destroy rubber safety flooring. Effective commercial floor cleaning requires matching your approach to your actual surfaces. Here's how to prevent slippery floors based on floor type.

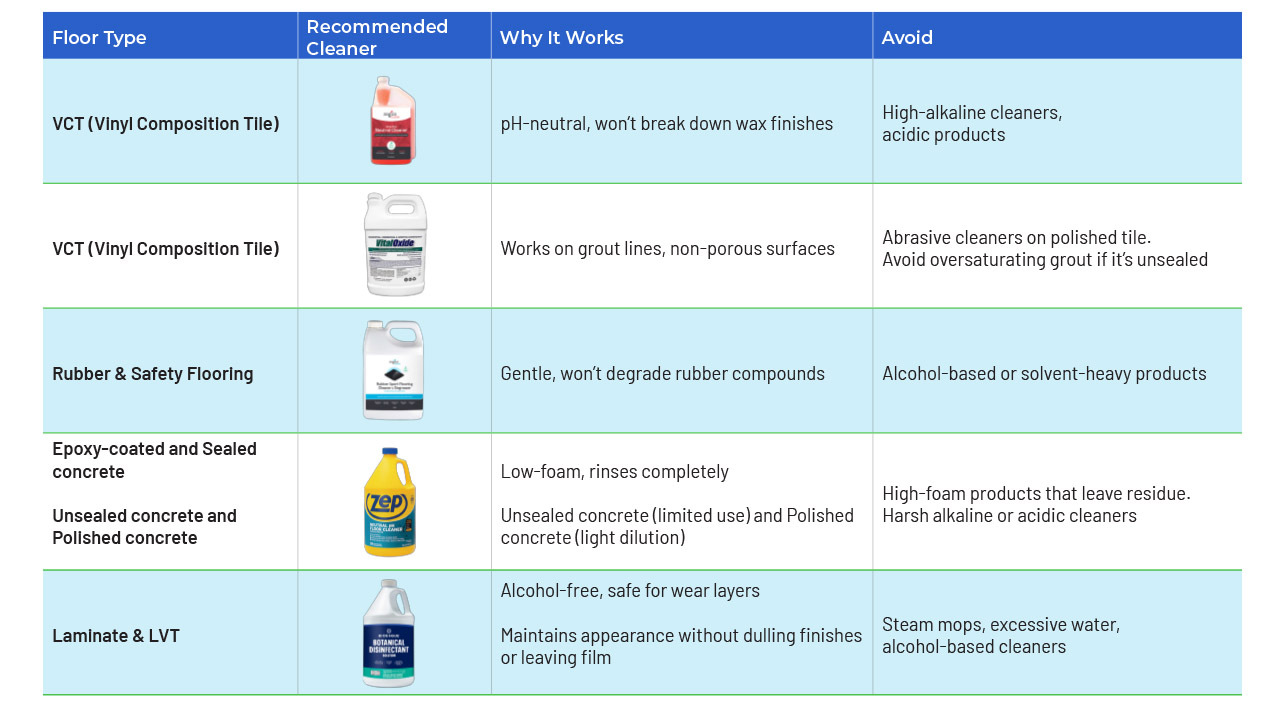

Quick Reference: Preferred Cleaners by Floor Type

Vinyl Composition Tile (VCT) - The Wax Problem

The Issue: VCT is everywhere in commercial facilities—schools, hospitals, office buildings. Most VCT has a wax or acrylic finish that gives it shine. The problem is, many disinfectants soften or break down these finishes, leaving a slick coating that's neither wax nor clean floor. This is why cleaning VCT floors without streaks requires specific products and techniques.

Healthcare Facilities: In hospitals and clinics, you're disinfecting VCT multiple times per shift with EPA-registered disinfectants. Each pass with the wrong product degrades the finish a bit more. Within weeks, you've got a floor that looks clean but feels like a skating rink.

How to Fix It:

Use pH-neutral floor cleaner for routine cleaning between deep disinfections. Zogics Neutral Floor Cleaner Concentrate is specifically formulated to work with waxed finishes without breaking them down.

Manual Mopping: Use a microfiber mop with a microfiber pad for VCT. The low-moisture application protects the wax finish while the microfiber captures dirt without scratching. Change pads frequently—dirty pads redistribute residue and can streak the finish.

Machine Mopping: For large VCT installations, use an automatic scrubber with soft nylon or polypropylene brushes (avoid abrasive brushes that damage wax). Set the machine to low pressure and use minimal solution flow to prevent oversaturation. Follow with a dry vacuum pass to remove all moisture and residue. For high-shine results, use a burnisher with a red or beige buffing pad after cleaning.

When you need to disinfect (not just clean), use Zogics Hypochlorous Acid Disinfectant. It kills pathogens without leaving the residue that quats create—making it an ideal residue-free floor disinfectant.

After disinfecting, do a water-rinse pass with a clean mop. This removes any remaining film before it dries and hardens.

Maintenance Schedule: Strip and wax floors every 6-12 months. As finishes age, they become more reactive to chemicals, making slip hazards more likely.

Ceramic and Porcelain Tile - The Grout Line Trap

The Issue: Smooth tile surfaces don't hold much residue, but grout lines are another story. Textured tiles and grout absorb disinfectant, then release it slowly as moisture, creating wet spots that dry unevenly. Recent studies on evaporation residue found that microscopic residues can persist on glass and tile surfaces even after visible moisture evaporates—especially in humid environments—proving why proper airflow and drying are critical for tile floors. This explains why many facilities struggle with how to clean ceramic tile floors without leaving slippery residue.

Gyms and Locker Rooms: These spaces have tile floors plus high humidity—a perfect storm for slippery conditions. Gym floor cleaning requires special attention because body oils and soap residue from showers compound the problem, creating surfaces that resist drying even with proper products.

How to Fix It:

Scrub grout lines during cleaning, not just the tile surface. Residue hides in texture.

Manual Mopping: Use a dual-bucket mop system with microfiber mop with a figure-eight mopping pattern to ensure grout lines get proper attention. For textured tile, consider a microfiber string mop (not cotton) that can work solution into grout joints. The key is wringing thoroughly—ceramic tile shows water spots easily if over-wet. Work in manageable sections and change mop water frequently in high-traffic areas.

Machine Mopping: Automatic scrubbers with cylindrical brush heads work best for tile and grout. The rotating brushes agitate grout lines effectively while the vacuum system removes dirty solution immediately. Use medium-stiff brushes for textured tile, softer brushes for polished surfaces. Set adequate down pressure to work solution into grout without damaging tile edges. For large areas, walk-behind scrubbers dramatically reduce labor time while improving cleaning consistency.

Use a quaternary disinfectant cleaner at proper dilution on ceramic tiles. It's effective against common gym pathogens without leaving heavy residue when mixed correctly.

For eco-conscious facilities, Bioesque Botanical Disinfectant Solution provides plant-based disinfection that dries clean with minimal film—a great option for those seeking the best cleaner for ceramic tile floors.

Deploy commercial fans in high-humidity areas. Don't wait for natural drying—force it with airflow to prevent wet floor safety issues.

Rubber and Safety Flooring - The Degradation Risk

The Issue: Rubber floors are installed specifically for slip resistance—weight rooms, play areas, and commercial kitchens. But alcohol-based and solvent-heavy disinfectants can actually soften rubber compounds, reducing the very texture that provides grip. Understanding how to clean rubber floors properly protects your investment in slip-resistant flooring.

Schools and Daycare Centers: These facilities need frequent disinfection due to high touch and spill rates, but they also need flooring that stays slip-resistant for children's safety. School floor maintenance requires products that won't damage the surface. Using the wrong disinfectant here doesn't just create slip hazards—it permanently damages expensive flooring.

How to Fix It:

Avoid alcohol-based disinfectants on rubber completely. Check labels—many "broad-spectrum" disinfectants contain high alcohol content.

Manual Mopping: Use microfiber flat mops with white or tan pads (colored pads can transfer dye to light rubber). Apply solution sparingly—rubber flooring is non-porous and doesn't need heavy saturation. After mopping, follow with a dry microfiber cloth to buff the surface and restore natural grip. Never use string mops on rubber; they hold too much water and can cause seam damage.

Machine Mopping: For large rubber installations (gyms, weight rooms), use automatic scrubbers with soft brush heads or pad drivers with red or beige buffing pads. Avoid aggressive black or brown stripping pads that can damage the rubber texture. Use minimal water flow and ensure complete vacuum pickup—standing water can penetrate seams and damage subflooring. Some facilities prefer air-powered sweeper-scrubbers for rubber because they provide excellent moisture control.

Choose non-corrosive, pH-neutral formulas. Zogics Rubber Floor Cleaner & Degreaser is gentle on rubber while still achieving kill times for relevant pathogens.

After mopping, dry buff with microfiber cloths. This removes any surface moisture and restores the natural grip of the rubber texture.

For quick spot disinfection, Zogics ecoPRO Wipes work without leaving residue that builds up over time.

Concrete and Epoxy - The Sealer Complication

The Issue: Warehouses, industrial kitchens, and manufacturing floors often have sealed concrete or epoxy coatings. Porous concrete traps cleaning solutions deep in its structure. Epoxy can develop a smooth, almost glassy finish when certain disinfectants interact with the coating. Proper cleaning concrete floors in commercial settings requires understanding these chemical interactions.

Food Service and Industrial Settings: These environments demand powerful disinfection due to contamination risks, but they also see constant foot traffic. A slippery floor in a commercial kitchen isn't just inconvenient—it's a liability nightmare when someone's carrying hot equipment or sharp tools. Commercial kitchen floor cleaners must balance disinfection power with safe traction.

How to Fix It:

Use low-foam floor cleaners that rinse completely. High-foam products leave residue in concrete's porous structure and create slippery conditions.

Manual Mopping: For sealed concrete, use heavy-duty microfiber flat mops with thick pads that can handle uneven surfaces. For bare concrete, microfiber string mops work better to work solution into the porous surface. Always use a double-bucket system and change solution frequently—concrete floors get dirty fast and you don't want to mop with contaminated water. Consider a deck brush or utility brush for heavily soiled areas before mopping.

Machine Mopping: Concrete and epoxy floors benefit most from automatic scrubbers. Use stiff brushes for bare concrete to scrub solution into pores, then vacuum immediately to extract trapped dirt. For epoxy coatings, use medium-soft brushes to avoid scratching the finish. Adjust water flow higher for bare concrete (it absorbs more) and lower for sealed/epoxy surfaces. Consider using a burnisher attachment for epoxy to restore shine after cleaning. Walk-behind or ride-on scrubbers make quick work of warehouse-sized concrete floors.

Follow disinfection with a neutral cleaner pass. Zep Neutral Floor Cleaner, Fresh Scent removes disinfectant residue without damaging sealants—perfect for removing residue from floors after disinfection.

Inspect sealants regularly. Deteriorating coatings change how chemicals interact with the surface, creating unpredictable traction issues.

Use microfiber flat mops or commercial mop systems that apply thin, even layers of solution. Flooding concrete floors extends dry time and increases slip risk—proper technique is the best way to clean floors without residue.

Laminate and Luxury Vinyl Tile (LVT) - The Coating Conflict

The Issue: Modern laminate and LVT have protective wear layers that resist scratches and stains. These same coatings can react badly to high-alkaline or quat-heavy disinfectants, creating streaky films that feel slippery. Learning how to clean laminate floors without residue is essential for maintaining both appearance and safety.

Corporate Offices: Executive offices, conference rooms, and reception areas often have high-end LVT that needs to look immaculate. But if it feels slippery after cleaning, it creates immediate complaints—and potential liability.

How to Fix It:

Avoid high-pH cleaners and quat-heavy disinfectants. Check product specifications before use.

Use low-moisture application methods. LVT and laminate can't handle saturated mopping.

Manual Mopping: Laminate and LVT require the lightest touch. Use microfiber flat mops with barely-damp pads—these floors cannot tolerate excess moisture. Spray solution directly onto the pad rather than the floor to control application. Work in small sections and dry immediately with a second clean microfiber pad. Never use wet string mops or steam mops on laminate—moisture can penetrate seams and cause swelling.

Machine Mopping: Small commercial-grade spray mops work well for LVT maintenance in offices and hallways. For larger areas, use automatic scrubbers with soft pad drivers (no brushes) and minimal water flow. The key is immediate vacuum pickup—leave no standing water. Some facilities prefer orbital floor machines with microfiber bonnets for LVT; these clean effectively with almost no moisture and eliminate slip risk entirely. Battery-powered spray mops offer excellent moisture control for sensitive laminate installations.

Choose alcohol-free disinfectants designed for coated surfaces that are safe for laminate wear layers.

For routine maintenance, Emerald Optically Enhanced Neutral Floor Cleaner maintains appearance without dulling finishes or leaving film.

Dry with microfiber—never cotton. Cotton mops leave lint and don't absorb residue effectively.

Custodian Safety: Protecting Your Team While Protecting Your Floors

Slippery floors after disinfecting aren't just about liability to building occupants—they're an occupational hazard for the people doing the cleaning. Workplace floor safety starts with protecting your custodial staff.

The Hidden Risk to Cleaning Staff

According to the National Floor Safety Institute (NFSI), slips and falls cause over 1 million hospital emergency room visits annually in the United States. Environmental conditions like humidity also affect residue persistence; the Cambridge evaporation kinetics study demonstrated how slower evaporation rates increase surface film formation—especially relevant in low-ventilation areas.

Custodial workers face disproportionate risk because they're working on wet surfaces constantly, often while carrying equipment, pushing carts, or moving backward while mopping. Custodial staff safety requires proper training, equipment, and protocols.

Real-World Safety Protocols That Actually Work

Signage Isn't Optional: "Wet Floor" signs seem obvious, but they're legally required in most jurisdictions during and after cleaning. Place them before you start mopping, not after someone slips. Proper wet floor safety signage is a critical first line of defense.

Respect Dwell Time: Every disinfectant has a required contact time to kill pathogens—usually 5-10 minutes. Understanding disinfectant dwell time is crucial: rushing foot traffic back onto floors before this time is up doesn't just create slip hazards; it makes the disinfection ineffective.

Control the Environment: In areas with poor ventilation or high humidity, use fans or air movers to accelerate drying. Don't just wait and hope floors dry faster—this is especially important for healthcare facility floor care where humidity control matters.

Document Everything: Keep logs of when areas were cleaned, which products were used, and any incidents reported. Meeting OSHA slip and fall requirements means maintaining documentation, and it protects your facility if slip-and-fall claims arise.

Train on Proper Dilution: Provide measuring tools—not just instructions. A squeeze bottle with marked measurements ensures consistency across all staff members and prevents the dilution errors that cause residue buildup.

Need Help Choosing the Right Products for Your Facility?

Every facility is different. Floor types, traffic patterns, budget constraints, and compliance requirements all factor into what works best. Finding the best floor disinfectant and cleaning system for your specific needs requires expert guidance.

Our team at The Cleaning Station specializes in matching custodial teams with janitorial floor cleaning products that actually solve problems—not just check boxes.

Browse All Commercial Floor Cleaning Supplies →

Final Takeaway: Clean Doesn't Have to Mean Slippery

Slippery floors after disinfecting aren't a necessary evil—they're a solvable problem. The solution isn't choosing between hygiene and safety; it's understanding the chemistry of what you're using and matching it to your surfaces. Effective slip and fall prevention requires the right products, proper techniques, and ongoing vigilance.

Three things eliminate post-disinfection slip hazards:

1. Use low-residue disinfectants formulated to dry clean without leaving films—look for residue free floor disinfectants specifically designed for commercial use

2. Follow proper dilution and application techniques that prevent over-saturation and residue buildup

3. Match products to floor types because what works on tile destroys rubber—understanding floor finish compatibility is essential

Facilities that implement these practices see dramatic reductions in slip incidents, lower liability exposure, and happier custodial teams who aren't constantly fielding complaints.

Ready to make your floors both clean and safe? The Cleaning Station carries professional-grade, low-residue floor care products designed specifically for commercial facilities. Find everything from industrial floor cleaners to bulk floor cleaning supplies.

Shop Floor Disinfectants | Shop Commercial Cleaning Tools →

Frequently Asked Questions

Why do my floors feel sticky after mopping?

Dry doesn't mean residue-free. Many disinfectants—especially quaternary ammonium disinfectants—leave invisible films that reduce traction even when moisture has evaporated. This film is what causes slippery floors even hours after cleaning. Switching to low-residue options like Zogics Hypochlorous Acid Disinfectant eliminates this problem because these formulas don't leave chemical coatings behind.

Can I skip rinsing after disinfecting if I'm short on time?

It depends entirely on the product label. Many EPA-registered disinfectants specifically require a rinse step, especially on food-contact surfaces or areas with heavy foot traffic. Skipping the rinse leaves residue that creates slip hazards. If time is an issue, use no-rinse formulas like Zogics Hypochlorous Acid or Bioesque Botanical that are designed to dry clean without a rinse step.

How long to let disinfectant dry on floors before reopening to traffic?

Follow the product's dwell time (usually 5-10 minutes for disinfection), then allow complete drying. In normal conditions with good airflow, this means 15-20 minutes total. In humid environments, it can take 30-45 minutes or more. The floor should feel completely dry to the touch, and the coefficient of friction flooring measurement should test at ≥0.5 before removing "Wet Floor" signs. Using fans or air movers cuts dry time significantly.

What is the best mop for not leaving streaks and preventing slippery floors?

Microfiber flat mops are your best option for preventing slippery floors. They spread solution evenly in thin layers and absorb excess moisture that would otherwise sit on the surface. Use dual-bucket systems that keep clean and dirty water separated—this prevents you from mopping with increasingly dirty, residue-laden water. Avoid cotton string mops entirely; they hold too much water, release it unevenly, and extend dry time dramatically. A quality microfiber mop system is essential for how to fix slippery floors after cleaning.

Which disinfectants are safe for rubber or safety flooring?

Rubber flooring requires special care because many disinfectants contain solvents or high alcohol content that degrades rubber compounds. Stick with pH-neutral, non-corrosive formulas. Zogics Hypochlorous Acid Disinfectant and Bioesque Botanical Solution both work effectively on rubber without causing damage. Always check with your flooring manufacturer's maintenance guide to verify compatibility.

What should I do if floors are still slippery after switching products?

Start with a process audit. Check actual dilution ratios—staff may not be following instructions about proper dilution ratios for cleaning. Verify you're using the correct product for your specific floor type. Inspect mop heads; worn microfiber doesn't absorb residue properly. If floors feel tacky or sticky after cleaning, do a neutral cleaner rinse using Zogics All Surface Neutral Cleaner to remove residue from floors. Document all incidents with photos, times, and conditions for OSHA compliance and pattern analysis. This systematic approach shows you how to make floors less slippery even when initial product changes don't solve the problem.

Do slip-resistant floor coatings help with slippery floors?

Yes, but they're not a substitute for proper cleaning. Slip-resistant floor coatings or treatments add texture to smooth surfaces, increasing traction in wet conditions. They work best in consistently high-moisture areas like entryways, locker rooms, or commercial kitchens where slip-resistant flooring is essential. However, coatings can't compensate for heavy residue from improper disinfection. Use them as an additional safety layer, not a fix for bad cleaning practices. Make sure any coating you apply is compatible with your daily disinfectants to maintain both the coating and floor traction.

Recent Posts

-

If you're a facility manager, you've probably noticed the pattern: some cleaners finish their zones …Jan 30, 2026

-

High-Touch Surface Cleaning Checklist & Guide for Facilities

Overview: What This Guide Covers This guide provides a complete, ready-to-use high-touch surface cle …Jan 16, 2026 -

Facility HVAC Cleaning Checklist: What to Clean, When, and Why

The Dust You Don't See In many facilities, floors get cleaned, windows shine, and restrooms are sani …Jan 09, 2026