Facility HVAC Cleaning Checklist: What to Clean, When, and Why

The Dust You Don't See

In many facilities, floors get cleaned, windows shine, and restrooms are sanitized — but one look up may tell a different story. Dust rings around ceiling diffusers, clogged return vents, or a faint musty odor might go unnoticed because they're out of direct line of sight.

Yet these are fairly common signs that parts of your HVAC system need maintenance — and they matter more than most facility managers realize. Dirty vents, clogged filters, or neglected coils don't just sit there collecting dust—they actively circulate contaminants throughout occupied spaces. Every time the HVAC system runs, it pulls air through those dirty components, redistributing dust, allergens, mold spores, and other particulates back into the breathing zone.

The result? Undermined indoor air quality (IAQ), reduced occupant comfort, compromised energy efficiency, and an overall perception that the facility isn't as clean as it could be—even when your custodial team is doing everything right on the ground level.

That's why this HVAC maintenance checklist exists: to offer a clear, realistic, facility-ready guide on what to clean, when, and why—so air stays fresh, HVAC systems run efficiently, and spaces genuinely feel clean from floor to ceiling. We'll cover the components most commonly overlooked, the cleaning frequencies backed by research and industry standards, and practical tips for dividing responsibilities between custodial and maintenance teams.

Why HVAC Cleaning Matters — Air Quality, Efficiency & Perception

Air Quality & Health

Cleaner air starts at the filter—but it doesn't end there. A comprehensive approach to HVAC maintenance addresses the entire air pathway, from intake to distribution.

A widely cited review on indoor air quality shows that indoor air pollutants—dust, allergens, particulates, volatile organic compounds (VOCs), and biological contaminants—pose serious health risks, including respiratory and cardiovascular disease, when not properly filtered or ventilated. The study emphasizes that using air filters and cleaners correctly helps reduce those risks significantly.

But here's what many facility managers don't realize: a brand-new, high-efficiency filter can only do so much if the coils behind it are caked with dust, or if the ductwork upstream is contaminated. When filters clog beyond capacity, the system either bypasses air around the filter (reducing filtration efficiency) or pulls harder to compensate (increasing energy use and strain on components).

Ignoring clogged filters or dirty coils means recirculating the same contaminants repeatedly—creating a closed loop where pollutants never truly leave the building. In high-occupancy facilities like schools, offices, gyms, or healthcare settings, this can lead to:

• Increased absenteeism due to respiratory issues

• Complaints about stuffiness, odors, or poor air circulation

• Aggravated allergies and asthma symptoms

• Reduced cognitive performance (yes, air quality affects focus and productivity)

• Higher risk of airborne disease transmission in enclosed spaces

The solution isn't just changing filters more often—it's maintaining the entire system so that clean air actually reaches occupants.

System Performance & Energy Efficiency

Here's where HVAC maintenance becomes a dollars-and-cents conversation. Dirty systems don't just compromise air quality—they cost real money in wasted energy and premature equipment failure. The benefits of HVAC cleaning extend beyond air quality to tangible financial returns.

Recent research shows that routine HVAC cleaning significantly improves system performance. In one multi-climate study on HVAC cleaning impacts, properly cleaned HVAC systems delivered 10–46% more airflow and reduced blower/fan energy consumption by 41–60% compared to neglected systems.

Let's break down what that means in practical terms:

More Airflow = Better Comfort. When coils are clean, and filters aren't clogged, air moves freely through the system. Spaces heat and cool more evenly. Hot and cold spots disappear. Occupants stop complaining about stuffy conference rooms or freezing workstations.

Less Energy Consumption = Lower Utility Bills. A system struggling to push air through dirty components works harder and runs longer to achieve the same temperature setpoint. Motors run hotter. Compressors cycle more frequently. All of that translates directly to higher energy bills—sometimes 20-30% higher than a well-maintained system.

Reduced Strain = Longer Equipment Life. HVAC systems aren't cheap. A rooftop unit can cost $15,000-$50,000+ to replace. Neglecting routine cleaning shortens the lifespan of expensive equipment. Clean systems experience less mechanical stress, fewer breakdowns, and longer service intervals before major component replacement becomes necessary.

Think of it this way: spending a few hundred dollars on routine coil cleaning and filter changes can save thousands in emergency repairs and premature replacements. It's preventive maintenance that actually pays for itself.

Perception & Comfort

Beyond numbers, visible cleanliness (clean vent grilles, dust-free diffusers) and proper airflow reassure occupants. A facility that cares about air cleanliness often feels more professional, healthy, and trustworthy.

The Most Overlooked HVAC Cleaning Tasks

Even with active custodial regimes, these HVAC-adjacent tasks are often missed—not because teams don't care, but because they're literally out of sight and out of mind. Here's what typically gets overlooked and why it matters:

Ceiling Diffusers and Air Return Vents

These are the most visible signs of HVAC neglect—dust halos or dark rings around ceiling vents and returns. They're easy to miss because they're overhead, and custodial teams are typically focused on horizontal surfaces at eye level or below.

But here's the thing: those dust rings aren't just cosmetic issues. They indicate that unfiltered air is being drawn in (for returns) or distributed out (for diffusers) through a layer of accumulated dust. Every time the system cycles, that dust gets disturbed and becomes airborne again.

Why it's overlooked: Requires ladders or extension tools. Not part of traditional floor-level cleaning routines. Often seen as "maintenance's job" rather than custodial responsibility.

Exhaust Vents in High-Moisture or High-Use Areas

Breakroom and restroom exhaust vents are subject to unique challenges. Breakrooms accumulate cooking grease, food particles, and humidity. Restrooms deal with moisture, soap residue, and occasionally biological contaminants.

These vents work hard to remove contaminated air from the space, which means they accumulate more grime faster than supply vents. A clogged or dirty exhaust vent can't do its job effectively—leading to odor problems, moisture buildup, and poor air exchange.

Product Tip: For breakroom exhaust vents with grease buildup, use a grease-removing cleaner safe for plastics and metals. For restroom exhaust vents, use a restroom cleaner that provides effective cleaning with antimicrobial properties without harsh chemical odors.

Why it's overlooked: Located in areas cleaned frequently for other reasons, so teams assume vents are being handled. Often requires specialized degreasing or mold-safe cleaning products.

Filter Housings, Fan-Coil Covers, Drain Pans, and Condensate Trays

These components are typically accessed during filter changes or maintenance visits, but rarely cleaned beyond basic wipe-downs. Over time, filter housings accumulate dust bypass around filter edges. Drain pans and condensate trays can harbor mold, algae, and biofilm—especially in humid climates or during the cooling season.

When drain lines become clogged with biological growth, condensate backs up and can cause water damage, mold growth in hidden spaces, or system shutdowns.

Why it's overlooked: Requires system access that custodial teams typically don't have. Maintenance teams focus on mechanical function (filter changes, drain line clearing) but not on the cleanliness of the housing itself.

Intake Grilles Near Doors or High-Traffic Corridors

Intake grilles in entryways, lobbies, or near loading docks pull in outdoor air along with outdoor contaminants—dust, pollen, dirt, debris, and even exhaust fumes from nearby traffic. These grilles can clog quickly and dramatically reduce system efficiency.

A clogged intake means the system can't bring in adequate fresh air for ventilation. That leads to poor indoor air quality, CO₂ buildup in occupied spaces, and increased reliance on recirculated air (which may already be contaminated).

Why it's overlooked: Often positioned low to the ground or in hard-to-reach corners. It may be mistaken for "outdoor equipment" and assumed to be "self-cleaning" by the weather. Not part of regular interior cleaning routes.

When these tasks are ignored, clean floors and surfaces only mask the real problem—poor air quality and compromised system performance.

Product Tip: For hard-to-reach ceiling diffusers and high vents, use an extendable duster or microfiber mop head. The non-residue formula means you won't be creating a dust-attracting film on surfaces that are difficult to re-clean frequently.

HVAC Maintenance Checklist: Cleaning Frequency Guide with Recommended Products

Here's a practical HVAC cleaning checklist and HVAC maintenance checklist that facility managers can follow. This checklist is also available for download.

|

Component |

Recommended Frequency |

Responsible Team |

How to Clean + Recommended Products |

|

Ceiling Diffusers & Grilles |

Wipe visible dust weekly; deep clean monthly |

Custodial / Janitorial |

1. Vacuum with a soft brush attachment or dust with an extendable duster to remove loose dust. 2. Wipe with diluted neutral pH Zogics All-Surface Neutral Cleaner using a microfiber cloth. For quick touch-ups, Zogics Hand & Surface Sanitizing Wipes also work well. 3. For greasy areas, use Zogics Peroxide Powered Cleaner Degreaser (light dilution). 4. Rinse with clean water and dry to prevent dust from sticking. |

|

Air Return Vents |

Monthly |

Custodial |

1. Vacuum first using a soft brush attachment to remove dust, lint, and debris. 2. Wipe with diluted neutral pH Misco Hi-Con Neutral Disinfectant & Detergent using a microfiber cloth. For fast, routine touch-ups, Zogics Biodegradable Disinfectant Wipes are a safe, effective option. 3. For stuck-on grime, use Misco E01 Peroxide Powered Cleaner Degreaser (light dilution). 4. Rinse with clean water and dry to prevent new dust from sticking. |

|

Filters |

Every 1–3 months (or per manufacturer / occupancy level) |

Maintenance |

MERV 8-13 pleated filters (consider MERV 7–13 for shared spaces); properly dispose of used filters |

|

Evaporator / Condenser Coils |

Twice per year (spring & fall), or as needed based on inspection |

HVAC Maintenance Team / Contractor |

Evaporator Coils (Indoor) 1. Power off. 2. Vacuum lightly. 3. Use non-acid, no-rinse coil cleaner (or Bioesque Botanical Disinfectant Solution, or any mild biodegradable detergent if diluted). 4. Rinse if needed; let dry. Condenser Coils (Outdoor) 1. Power off. 2. Rinse with low-pressure water. 3. Use foaming alkaline coil cleaner (or diluted Misco E07 All Surface Neutral Cleaner for light soil). 4. Rinse thoroughly. |

|

Drain Pans / Condensate Trays |

Twice per year |

HVAC Maintenance Team / Contractor |

1. Turn off the power. 2. Remove standing water. 3. Clean the pan with a mild detergent or Zogics All-Surface Neutral Cleaner. For light surface wipe-downs—not full cleaning—Zogics Hand & Surface Sanitizing Wipes can be used as a finishing step. 4. Rinse thoroughly and dry. 5. Add condensate pan tablets or an enzymatic cleaner to prevent algae and mold. |

|

Supply Ductwork (if serviced) |

Visual inspection annually; deep clean every 3–5 years (or as needed) |

Certified HVAC / Duct Contractor |

Use a HEPA-filtered vacuum system; avoid chemical sealants unless recommended by the EPA duct cleaning guidance |

Pro tip: Align coil cleaning and filter replacement with quarterly maintenance schedules — bundling tasks ensures nothing slips through the cracks.

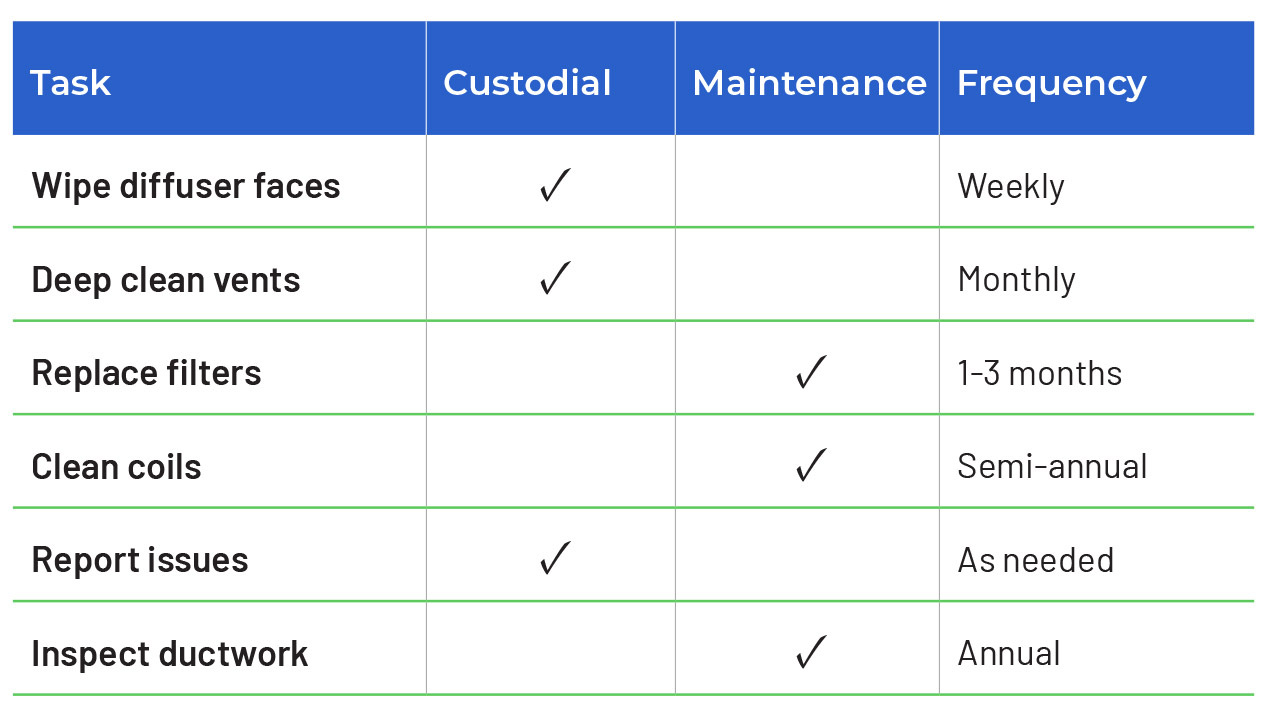

Cleaning vs Servicing — Clarifying Roles for Custodial & Maintenance Teams

One of the biggest reasons HVAC systems get neglected is unclear responsibility. Tasks fall through the cracks because no one knows whose job they are. To ensure accountability and prevent gaps, establish clear boundaries:

Custodial / Janitorial Team Responsibilities

What they handle: Superficial, visible, non-mechanical tasks

• Wiping dust from diffuser faces and grilles using extension dusters

• Vacuuming or wiping return vent covers (without removing them)

• Cleaning around the vent perimeters on walls and ceilings

• Reporting visible issues (excessive dust buildup, musty odors, moisture stains)

• Maintaining the cleanliness of accessible HVAC surfaces

Key limitation: No access to internal system components, no mechanical work, no filter replacement (unless specifically trained and authorized)

Maintenance / HVAC Team Responsibilities

What they handle: Mechanical, technical, and internal system tasks

• Replacing air filters on schedule (and checking pressure drop or airflow)

• Cleaning evaporator and condenser coils using appropriate detergents

• Servicing drain pans, clearing condensate lines, and treating with mold inhibitors

• Inspecting ductwork for leaks, damage, or contamination

• Lubricating motors, checking belt tension, and verifying proper airflow

• Responding to system performance issues or breakdowns

Key limitation: Often reactive rather than proactive—they fix what breaks, but may not prioritize preventive surface cleaning

Facility Management / Supervisors' Role

What they coordinate:

• Creating written cleaning schedules that specify custodial vs. maintenance tasks

• Tracking completion through work order systems or digital checklists

• Ensuring both teams communicate (e.g., custodial reports excessive dust → maintenance investigates filter or duct issues)

• Scheduling seasonal deep-cleans and ensuring they happen before peak HVAC load periods

• Budgeting for supplies, contractor services, and equipment upgrades

The critical handoff: When custodial teams notice something wrong (excessive dust reappearing quickly, musty odors persisting after cleaning, moisture around vents), they need a clear escalation path to maintenance. And when maintenance performs filter changes or coil cleaning, they should verify that custodial teams know to clean affected areas afterward.

Creating a Shared Responsibility Chart

Consider developing a simple matrix that both teams can reference:

This eliminates the "I thought they were doing it" problem and ensures every task has a clear owner.

Clear role definitions help prevent overlap and missed areas. When each team knows what's theirs, accountability improves—and so does air quality.

Understanding the "Why" Behind Each Frequency

Weekly/Monthly Visible Cleaning: Diffusers and grilles accumulate dust quickly in high-traffic or high-occupancy spaces. Weekly dusting prevents buildup from becoming baked-on or attracting moisture (which can lead to mold). Monthly deep cleaning ensures you're not just moving dust around but actually removing it.

When to clean HVAC filters depends on environmental factors. 1-3 Month Filter Replacement: Filter life depends heavily on the environment. A suburban office with low occupancy might stretch to 3 months. A school with 500+ students, or a facility near construction, may need monthly changes. The key indicator? Reduced airflow or visible dirt accumulation. Some facilities use pressure drop sensors to monitor filter condition in real-time rather than relying on time-based schedules alone.

Semi-Annual Coil Cleaning: Coils accumulate dust, biological growth, and chemical residues slowly. Cleaning them twice per year (typically before peak cooling and heating seasons) ensures optimal heat exchange efficiency. Dirty coils act as insulators, forcing the system to work harder and run longer. In extreme cases, neglected coils can lose 30-40% of their heat transfer capacity. Reference our fall HVAC maintenance checklist for seasonal preparation.

3-5 Year Duct Cleaning: Full duct cleaning is invasive, expensive, and only necessary when there's visible contamination or documented IAQ problems. However, visual inspections should happen annually—especially after renovations, water damage, or pest issues. If you see mold, dust accumulation thicker than 1/8 inch, or vermin evidence, it's time to clean regardless of the schedule.

Adjusting Frequencies for Your Facility

Not all facilities are created equal. Adjust these baseline recommendations based on:

• Occupancy levels: High-traffic spaces need more frequent attention

• Local environment: Desert climates = more dust; humid climates = more biological growth

• Facility type: Healthcare and food service require more stringent protocols

• Seasonal factors: Pollen season, wildfire smoke, and winter heating all affect HVAC load. Any seasonal HVAC maintenance guide should account for these variables.

• Recent events: Construction, renovations, water damage, or pest problems necessitate immediate attention

Seasonal Maintenance: Timing Your HVAC Care

HVAC systems work year-round, but seasonal transitions—spring warming, summer peak cooling, fall preparation, and winter heating demands—create critical maintenance windows. The downloadable checklist below includes a dedicated seasonal maintenance section that helps you prioritize the right tasks at the right time of year, ensuring your system is prepared before peak demand hits.

FREE DOWNLOAD: HVAC Maintenance Checklist — Complete Facility Maintenance Reference Guide

Get our comprehensive, printable HVAC maintenance checklist organized by frequency (weekly, monthly, semi-annual, annual, 3-5 years, and seasonal care) with clear team assignments. Perfect for facility managers to track all maintenance tasks throughout the year. Includes sections for custodial/janitorial teams, HVAC maintenance teams, and certified duct contractors—plus space for notes and observations.

What Clean Air Looks Like (and Feels Like)

You can't see airflow—but you can see (and sense) its results. Here's how to know your HVAC cleaning program is actually working:

Visual Indicators

• No dust rings or halos around vents and diffusers. Clean vents should have sharp, defined edges with no dark accumulation around perimeters. If you're constantly seeing "shadow lines" reappear within days of cleaning, it's a sign that air is bypassing filters or pulling unfiltered air through gaps.

• Consistent dust patterns across the facility. In a well-maintained space, dust accumulation should be relatively uniform. If one area collects significantly more dust than others despite similar foot traffic, investigate nearby vents—there may be excessive air velocity, dirty ductwork, or filter bypass happening.

• Clean, dry drain pans with no standing water or slime. When you open access panels, drain pans should be clean and dry (or with minimal condensate actively draining). Slimy buildup, standing water, or foul odors indicate biological growth that can compromise air quality and damage equipment.

Performance Indicators

• Consistent airflow across diffusers. Hold your hand under multiple diffusers in the same zone. Airflow should feel relatively consistent—not strong from one and weak from another. Imbalanced flow often indicates clogged filters, dirty coils, or duct obstructions.

• No hot/cold spots or pressure imbalances. Well-maintained systems distribute conditioned air evenly. If conference rooms overheat while private offices freeze, or if doors slam shut due to pressure differences, the system likely has airflow restrictions caused by dirty components.

• Faster heating/cooling cycles. Clean systems reach temperature setpoints more quickly because they're not fighting against restricted airflow or poor heat exchange. If your system seems to run constantly without achieving comfort, dirt and neglect are likely culprits.

Sensory Indicators

• Neutral or fresh indoor air—not stale, dusty, or musty. Properly maintained HVAC systems deliver air that doesn't have a noticeable smell. Musty odors indicate mold or biological growth somewhere in the air pathway. Dusty or stale odors suggest inadequate filtration or poor ventilation.

• No visible dust buildup on surfaces shortly after routine cleaning. If horizontal surfaces accumulate a visible layer of dust within hours of being wiped down, your HVAC system is actively distributing particulates into the space. This is a strong indicator that filters are inadequate or bypassed, or that ductwork is contaminated.

• Reduced allergy and respiratory complaints. This is perhaps the most important indicator: when occupants with allergies or sensitivities breathe easier and report fewer symptoms, you know your air quality efforts are working.

Many of these issues stem from what’s circulating through the HVAC system. Understanding common airborne contaminants—like dust, pollen, mold spores, and VOCs—can help explain why routine HVAC cleaning is so critical. Learn more in What’s in the Air We Breathe.

The Occupant Experience

At the end of the day, clean air creates a better experience for everyone in the building:

• Employees feel more alert and focused

• Students can concentrate better

• Gym members aren't coughing during workouts

• Patients recover in healthier environments

• Visitors perceive the facility as well-maintained and professional

Cleaner air isn't always visible—but the results often are. And when occupants notice (or better yet, don't notice because everything just works), you've succeeded.

Common HVAC Cleaning Mistakes That Undermine Your Efforts

Even well-intentioned teams can make mistakes that reduce effectiveness or cause damage. Avoid these critical errors:

Using the Wrong Cleaning Products

The mistake: Spraying glass cleaner, all-purpose cleaner with fragrance, or harsh chemicals directly on vents and diffusers.

Why it's a problem: Many cleaning products leave residues that attract more dust, or contain volatile organic compounds (VOCs) that get distributed throughout the building via the HVAC system. Fragranced products can trigger sensitivities in occupants with asthma or allergies.

The fix: Use fragrance-free, non-residue cleaning products specifically designed for HVAC components. Microfiber cloths slightly dampened with Neutral pH Cleaners are ideal for most vent and diffuser surfaces.

Neglecting to Coordinate Between Teams

The mistake: Maintenance replaces filters but doesn't inform custodial to clean the surrounding vents. Or custodial cleans vents but doesn't report excessive dust buildup that indicates a deeper system problem.

Why it's a problem: Both teams miss opportunities to address root causes. Cleaning vents while filters are clogged is pointless—they'll be dirty again within days. Similarly, replacing filters without cleaning the surrounding housings means contamination remains in the air pathway.

The fix: Implement a simple communication protocol. When maintenance does filter changes, they note any excessive dust and request custodial deep-clean of that zone. When custodial notices unusual buildup, they create a maintenance ticket for investigation.

Cleaning Vents While Systems Are Running

The mistake: Dusting or wiping vents while the HVAC system is actively pulling air.

Why it's a problem: Disturbed dust gets immediately pulled into the system and distributed to other areas. You're essentially making the problem worse by redistributing contaminants rather than removing them.

The fix: Coordinate with building operations to temporarily shut down HVAC zones during deep cleaning, or schedule vent cleaning during off-hours when systems are in setback mode.

Ignoring Drain Pans and Condensate Systems

The mistake: Focusing only on visible surfaces (vents, diffusers) while neglecting drain pans and condensate trays.

Why it's a problem: These hidden components are breeding grounds for mold, algae, and bacteria—especially in humid climates or during the cooling season. Contaminated drain pans can introduce musty odors and airborne spores into the air stream.

The fix: Include drain pan inspection and cleaning in semi-annual maintenance routines. Use enzymatic cleaners or condensate pan tablets (slow-release treatments) to prevent biological growth between cleanings. Products like mold inhibitor sprays provide additional protection in high-humidity environments or facilities and home HVAC maintenance checklist applications with chronic moisture issues.

Over-Relying on Time-Based Schedules

The mistake: Changing filters every 90 days like clockwork, regardless of actual condition or environmental factors.

Why it's a problem: A filter might be completely clogged after 30 days in a high-dust environment, or still have useful life after 120 days in a clean suburban office. Time-based schedules ignore reality and can lead to either premature replacement (wasted money) or extended use past effectiveness (compromised air quality).

The fix: Supplement time-based schedules with visual inspections and, ideally, pressure drop monitoring. Train maintenance staff to check filter condition during routine rounds and adjust replacement timing based on actual need.

Assuming "Out of Sight, Out of Mind" Works

The mistake: Only cleaning components that are visible or easily accessible.

Why it's a problem: The most critical HVAC components—coils, drain pans, ductwork—are hidden from view. By the time problems become visible (water stains, odors, system failures), damage has already occurred.

The fix: Build inspection and cleaning of hidden components into your preventive maintenance schedule. Use borescopes or inspection cameras to check inaccessible ductwork. Make invisible maintenance visible through documentation and scheduled reminders.

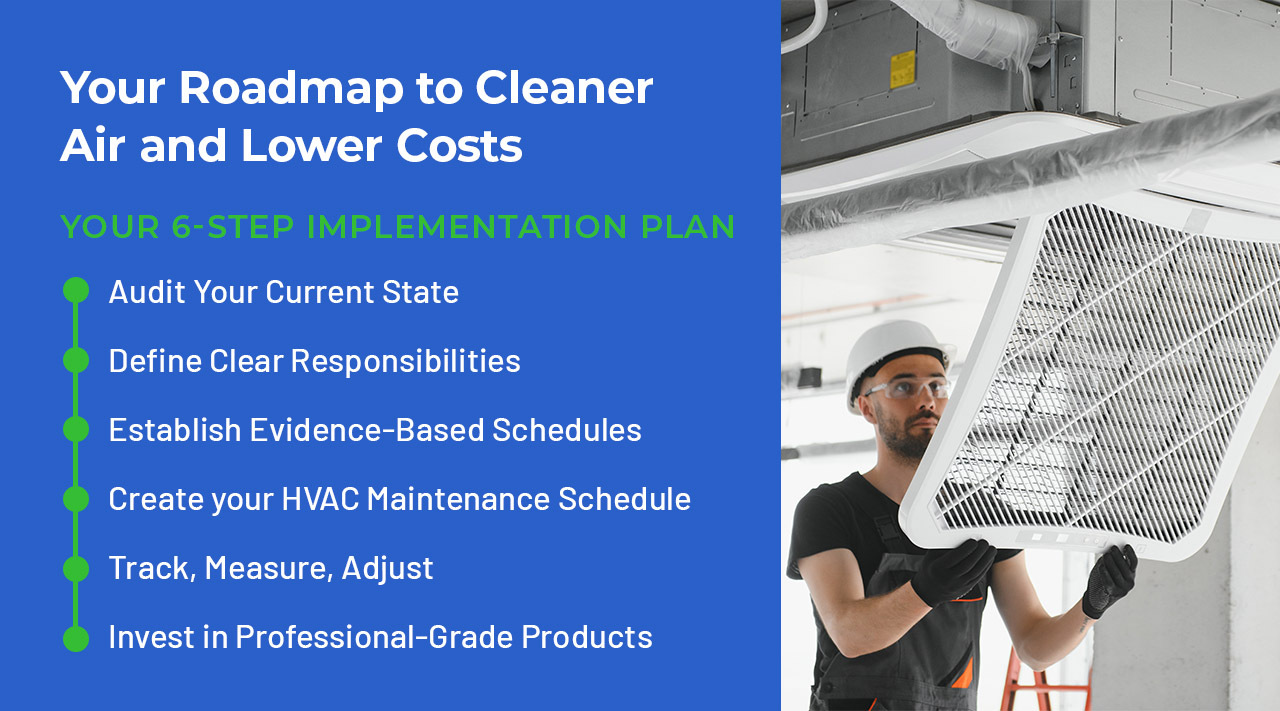

Take Action: Your Roadmap to Cleaner Air and Lower Costs

Clean HVAC systems don't just circulate air—they protect health, reduce energy waste, and create spaces where people actually want to be. The difference between a facility that "looks clean" and one that genuinely delivers clean air comes down to one thing: following an HVAC maintenance checklist that works.

Your 6-Step Implementation Plan

1. Audit Your Current State

Walk your facility with this checklist in hand. Photograph dust rings around vents, note musty odors, and check filter change dates. Create a priority list based on what you find—not what you assume.

2. Define Clear Responsibilities

Who cleans visible vents? Who changes filters? Who inspects coils? Create a simple responsibility matrix and share it with both custodial and maintenance teams. Post it where staff can reference it daily.

3. Establish Evidence-Based Schedules

Use the frequency guide in this article as your baseline, then adjust based on real-world conditions. High-traffic gyms need more frequent attention than low-occupancy offices. Let data—not guesswork—drive your schedule.

4. Create your HVAC Maintenance Schedule

Use the frequency guide in this article as your starting point, then adjust based on your facility's specific needs. High-traffic, high-occupancy, or high-dust environments need more frequent attention.

5. Track, Measure, Adjust

After 90 days, ask: Are vents staying cleaner? Are energy bills trending down? Are occupant complaints decreasing? Use objective data to refine your approach. What gets measured gets improved.

6. Invest in Professional-Grade Products

Equip custodial teams with fragrance-free, non-residue wipes, extension dusters, and color-coded microfiber cloths. Supply maintenance with pH-neutral coil cleaners, condensate pan tablets, and MERV 8-13 filters. Quality products aren't an expense—they're an investment in faster work, better results, and healthier air.

Browse All Cleaning Chemicals →

Stock Your Facility with the Right HVAC Cleaning Products

Professional-grade products designed for HVAC-adjacent surfaces ensure safe and effective cleaning without compromising air quality or system performance. The Cleaning Station specializes in fragrance-free, non-residue formulations specifically for facilities where air quality and occupant health are priorities.

This HVAC maintenance checklist is based on peer-reviewed research and EPA guidelines. Always follow manufacturer instructions and OSHA safety requirements for HVAC maintenance in your facility.

Shop Professional-Grade Cleaning Tools →

Frequently Asked Questions

Why is HVAC maintenance important?

HVAC maintenance protects three critical assets: your building's air quality, your equipment's lifespan, and your occupants' health and comfort. Neglected systems waste energy (costing 20-40% more to operate), fail prematurely (reducing equipment life by years), and circulate contaminated air that affects productivity and well-being. Regular maintenance prevents expensive emergency repairs, ensures regulatory compliance, and maintains the indoor environment your facility was designed to provide. It's not optional — it's infrastructure protection.

What's the impact of a dirty HVAC system on energy and costs?

Dirty filters and coils reduce airflow and force fans/blowers to work harder. A recent multi-site study on HVAC performance showed that cleaned HVAC systems delivered 10–46% more airflow and achieved 41–60% energy savings on fan/blower power compared with neglected systems.

Can custodial teams safely wipe vents and diffusers, or is a technician required?

Yes — custodial teams can (and should) handle visible dust and vent-face cleaning using non-residue wipes or microfiber dusters. Internal cleaning (filters, coils, drain pans) should remain with trained maintenance staff or HVAC techs for safety and compliance.

How often to change HVAC filter? By time or by dust load?

Both. A general rule is every 1–3 months for shared-space HVAC systems, but real-world conditions (high occupant counts, dust, pet dander, outdoor pollution) can shorten that interval. Many facilities benefit from pressure drop monitoring and smart filtration systems to gauge when filters are genuinely clogged and need replacement.

Does duct cleaning always improve indoor air quality?

Not always. According to the U.S. Environmental Protection Agency's guidance on duct cleaning, routine duct cleaning alone doesn't guarantee improved air quality — it should be done when there's visible dust, mold, or after major renovation work. However, when ducts are part of a full HVAC maintenance program (filters, coils, vents, cleanliness), airflow and IAQ benefits are more pronounced.

Why do I need to clean air ducts?

Air ducts act as the circulatory system of your HVAC — when they're contaminated with dust, mold, debris, or biological growth, every cycle redistributes those pollutants throughout your facility. Clean ducts ensure the air being heated or cooled actually arrives clean at the vents. Neglected ductwork can harbor allergens, irritants, and even odors that compromise indoor air quality no matter how often you change filters. Regular duct cleaning (every 3-5 years) prevents buildup from reaching problematic levels.

How often to clean air ducts?

Visual inspections can be done annually, but full cleanings are generally only needed every 3–5 years — or sooner if there's visible contamination, mold, water damage, or after major renovation/construction. Use qualified HVAC contractors when doing full duct cleanings to ensure proper vacuuming and air sealing, following EPA recommendations. Why clean air ducts? Because contaminated ductwork continuously reintroduces pollutants.

Recent Posts

-

If you're a facility manager, you've probably noticed the pattern: some cleaners finish their zones …Jan 30, 2026

-

High-Touch Surface Cleaning Checklist & Guide for Facilities

Overview: What This Guide Covers This guide provides a complete, ready-to-use high-touch surface cle …Jan 16, 2026 -

Facility HVAC Cleaning Checklist: What to Clean, When, and Why

The Dust You Don't See In many facilities, floors get cleaned, windows shine, and restrooms are sani …Jan 09, 2026