Sensitive Skin Cleaning: Low Irritant Disinfectants, Gloves, and Hand Care Stations

Facility managers often report that skin irritation ranks among the top three health complaints from custodial staff, leading to increased sick days, workers' compensation claims, and staff turnover. When your cleaning team experiences chemical burns, rashes, or chronic dermatitis, it impacts both their well-being and your facility's operational efficiency.

The challenge intensifies in healthcare facilities, schools, and food service environments where frequent disinfection requirements expose staff to harsh chemicals multiple times per shift. Modern commercial facilities need cleaning solutions that balance powerful disinfection with staff safety—protecting both your team's health and your bottom line.

Understanding Chemical Irritation in Commercial Cleaning

Professional cleaning staff face unique exposure risks that residential users rarely encounter. Custodians may handle concentrated cleaning solutions multiple times per shift, with prolonged exposure during tasks like restroom sanitization, floor stripping, and high-touch surface disinfection.

Common irritants in commercial cleaning products include:

• Quaternary ammonium compounds

• Sodium hypochlorite (bleach)

• Phenolic compounds

• Strong acids or alkalis used in descalers and degreasers

These chemicals can cause immediate reactions like contact dermatitis or develop into chronic conditions through repeated exposure.

The true cost of chemical irritation extends beyond medical expenses. Facilities experiencing high rates of skin irritation often see:

• Increased absenteeism

• Reduced productivity from staff working with painful conditions

• Higher training costs from turnover

• Potential OSHA violations for inadequate PPE or safety protocols

Selecting Low-Irritant Commercial Disinfectants

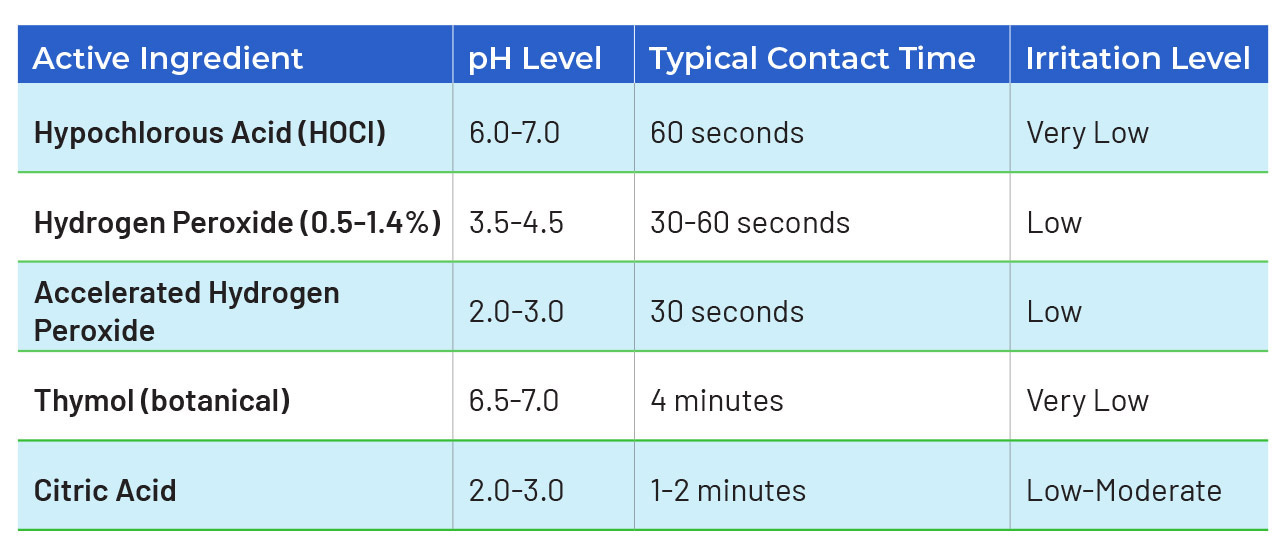

All disinfectants claiming to kill pathogens must be EPA-registered—the key is finding formulations that maintain this efficacy while reducing irritation potential. Modern EPA-registered disinfectants now offer hospital-grade effectiveness with significantly reduced skin irritation risk.

When evaluating low-irritant options, consider:

• pH-neutral formulations (6-8 pH range)

• Products with built-in skin conditioners

• Hydrogen peroxide-based solutions

• Hypochlorous acid (HOCl) formulations

• Disinfectants with shorter required contact times to minimize exposure duration

Recommended Low-Irritant Active Ingredients:

Proper dilution control systems reduce irritation risk while maintaining efficacy. Automated dilution not only prevents overconcentration but also helps maintain compliance with OSHA Hazard Communication standards by ensuring consistent, documented mixing ratios.

Featured Low-Irritant Products for Sensitive Skin Protection

Low-Irritant Disinfectants

Hypochlorous Acid Surface Disinfectant Our Zogics Hypochlorous Acid Ready-to-Use Surface Disinfectant represents the gold standard in gentle yet effective disinfection. With HOCl as its active ingredient—the same compound produced by white blood cells—this disinfectant offers:

• EPA-registered

• Non-toxic, non-irritating formula safe for frequent use

• No rinse required on food contact surfaces

• 60-second contact time for most pathogens

• Ideal for facilities prioritizing staff safety without compromising cleanliness

Plant-Based Disinfecting Wipes Our biodegradable disinfectant wipes combine environmental responsibility with skin-friendly formulations:

• Botanical active ingredients reduce irritation risk

• Pre-moistened for consistent application

• No harsh chemical residue

• Perfect for quick disinfection tasks throughout the day

• Available in bulk dispensers for high-traffic areas

Browse our complete selection of commercial disinfectants to find industrial-grade, lower-irritant formulas that meet your facility's specific needs while protecting staff health.

Professional Cleaning Gloves

Nitrile Disposable Gloves (Powder-Free): Using nitrile gloves for cleaning staff provides superior protection without latex allergen concerns:

• Available in multiple thicknesses (4-8 mil)

• Textured fingertips for secure grip

• Extended cuff options for forearm protection

• Powder-free to reduce skin irritation

• Color-coded options for task segregation

For heavy-duty applications requiring extended chemical contact, explore our full gloves category for neoprene and butyl rubber options that provide maximum protection during floor stripping and intensive cleaning tasks.

Hand Care Station Essentials

Touch-Free Hand Sanitizer Dispensers: Our hand sanitizer dispenser systems encourage frequent hand hygiene without cross-contamination:

• Automatic sensor activation

• Adjustable dispensing volume

• Battery-operated for flexible placement

• Compatible with gel and liquid sanitizers

• Available with tabletop or wall-mount options

Bulk Commercial Hand Sanitizer: Stock your dispensers with our bulk commercial hand sanitizer options:

• 70% alcohol formulations for maximum efficacy

• Added moisturizers to prevent skin drying

• Available in 1-gallon jugs and larger containers

• Fragrance-free options for sensitive skin

• Cost-effective bulk pricing for facility-wide deployment

All-in-One Sanitizing Stations Implement comprehensive hand care with our all-in-one sanitizing station:

• Integrated wipe dispenser

• Hand sanitizer dispenser

• Storage compartment for PPE

• Free-standing design for flexible placement

• Professional appearance for public-facing areas

Best Practices for Sensitive Skin Cleaning

1. Rotate Chemical Exposure: Implement rotation schedules that limit individual staff exposure to harsh chemicals. Assign different team members to high-exposure tasks on alternating days.

2. Time Management: Schedule intensive chemical use (like floor stripping) at shift end, allowing maximum recovery time before next exposure.

3. Environmental Controls: Ensure adequate ventilation during chemical use. Poor air circulation increases both respiratory and skin irritation risks.

4. Product Selection Strategy: Choose products based on specific task requirements rather than defaulting to the strongest available options. Many routine cleaning tasks can be effectively completed with gentler formulations like our hypochlorous acid surface disinfectant.

Commercial-Grade Hand Protection Systems

Professional glove selection requires balancing chemical resistance, dexterity, and comfort for extended wear. Custodial staff typically require multiple glove types for different tasks throughout their shift.

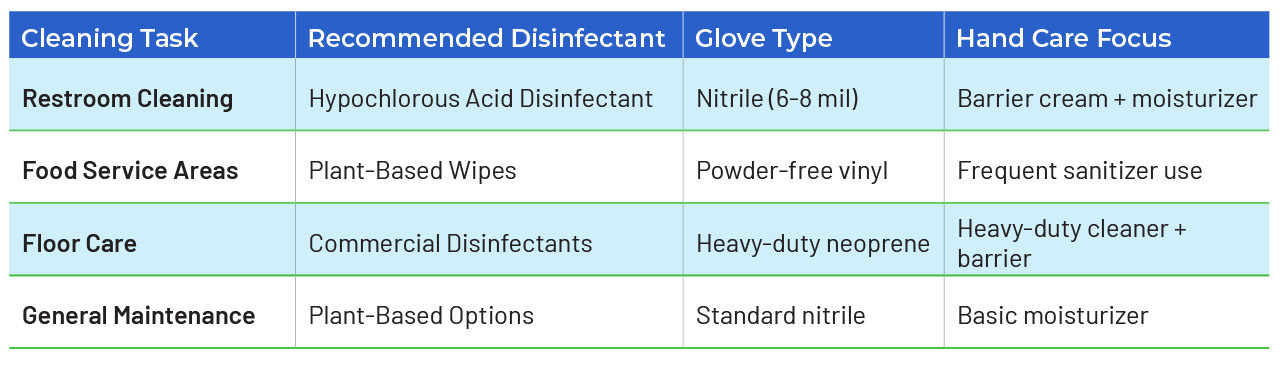

Task-Specific Glove Recommendations:

General Cleaning and Disinfection:

• Nitrile gloves (6-8 mil thickness)

• Excellent chemical resistance

• Minimal allergic reaction risk

• Textured grip for wet handling

Heavy-Duty Tasks (Floor Stripping, Deep Cleaning):

• Neoprene or butyl rubber gloves (15-22 mil)

• Extended chemical contact protection

• Forearm coverage options

Food Service Areas:

• Powder-free vinyl or nitrile

• FDA food handling compliant

• Color-coded options for task separation

Pro Tip: Double-gloving protocols provide additional protection for high-risk tasks. Wear thin nitrile inner gloves under task-specific outer gloves when handling concentrated chemicals.

Implementing Hand Care Stations

Strategic hand care station placement throughout your facility encourages proper skin protection protocols. Staff report that convenient access to hand care products increases usage compliance by 60-80%.

Essential Hand Care Station Components:

• Industrial hand cleaners - Remove stubborn soils without harsh solvents

• Barrier creams - Create protective layers before chemical exposure

• Moisturizing lotions - Restore skin's natural barrier function

• Instant hand sanitizers - For between-glove applications

Optimal Station Placement:

Position primary stations in:

• Custodial closets where staff prepare for shifts

• Near chemical storage areas for pre-exposure protection

• Break rooms for scheduled hand care breaks

• Adjacent to PPE storage for integrated safety protocols

Consider implementing our hand sanitizing station in high-traffic areas to ensure consistent access to hand hygiene resources.

Training Programs for Chemical Safety

Comprehensive staff training reduces irritation incidents while improving cleaning efficacy. Effective programs combine initial certification with ongoing reinforcement.

Core Training Modules:

• Chemical dilution procedures and the dangers of "stronger is better" misconceptions

• Proper PPE selection based on specific chemical hazards

• Recognition of early irritation symptoms before they become serious

• Emergency response protocols for chemical exposure incidents

Microlearning Approaches:

• Weekly 5-minute safety talks

• Posted infographics near hand care stations

• QR codes on chemical containers linking to handling videos

• Regular refresher quizzes with small incentives

Creating Facility-Specific Skin Protection Protocols

Effective skin protection protocols account for your facility's unique risk factors:

Step 1: Chemical Inventory Audit

Document all products currently used and their irritation potential based on Safety Data Sheets (SDS). Consider transitioning high-risk products to gentler alternatives like plant-based disinfecting wipes where appropriate.

Step 2: Develop Written Protocols

Specify:

• Required PPE for each chemical/task combination

• Mandatory hand care breaks (every 2 hours for high-exposure tasks)

• Rotation schedules to limit individual exposure

• Medical monitoring for early detection of developing conditions

Step 3: Implementation Timeline

• Week 1-2: Baseline measurement of current irritation incidents

• Week 3-4: Staff training and protocol introduction

• Month 2: Full implementation with daily monitoring

• Month 3: Assessment and protocol refinement

Product Selection Guide

Measuring and Monitoring Success

Track key performance indicators to validate your skin protection investments:

Primary Metrics:

• Monthly skin irritation incident reports

• Sick days attributed to dermatitis or chemical exposure

• Workers' compensation claims related to skin conditions

• PPE compliance rates through supervisor observation

Expected Outcomes:

Facilities implementing comprehensive skin protection programs typically see:

• 40-60% reduction in irritation incidents within first quarter

• Decreased absenteeism within 30 days

• Improved staff morale and retention

• Reduced workers' compensation premiums (6-12 month timeline)

Key Takeaway: Regular skin health assessments by occupational health professionals can identify subclinical irritation before it develops into serious conditions.

Budget-Conscious Implementation Strategies

Transitioning to low-irritant cleaning systems requires strategic budgeting to manage upfront costs while capturing long-term savings.

Phase Implementation Approach:

1. Identify Priority Areas: Start with departments showing highest irritation rates

2. Calculate Total Cost of Ownership:

∙ Product costs

∙ Training expenses

∙ Reduced sick days savings

∙ Lower turnover costs

∙ Decreased workers' compensation premiums

3. Leverage Volume Purchasing: Bundle orders of commercial disinfectants and bulk commercial hand sanitizer for maximum discounts

Return on Investment Timeline:

• Month 1-3: Initial investment in products and training

• Month 4-6: Measurable reduction in incidents

• Month 7-12: Break-even through reduced indirect costs

• Year 2+: Sustained savings and improved retention

Conclusion

Protecting custodial staff from chemical irritation isn't just about compliance—it's about creating sustainable cleaning operations that retain skilled workers while maintaining superior facility hygiene. By selecting low-irritant disinfectants, implementing comprehensive hand protection systems, and establishing robust training protocols, facilities can eliminate the false choice between worker safety and cleaning efficacy.

The path forward combines smart product selection, strategic implementation, and consistent monitoring to create a safer, more productive cleaning environment for your entire team.

Ready to protect your custodial team?

Start with our hypochlorous acid surface disinfectant and nitrile gloves for cleaning staff. Build complete hand care stations with our touch-free dispensers and bulk sanitizer options.

Related Resources:

- OSHA Hazard Communication Standards for Cleaning Chemicals

- CDC Guidelines for Environmental Infection Control

- Browse All Commercial Disinfectants

- Shop Plant-Based Cleaning Solutions

Recent Posts

-

If you're a facility manager, you've probably noticed the pattern: some cleaners finish their zones …Jan 30, 2026

-

High-Touch Surface Cleaning Checklist & Guide for Facilities

Overview: What This Guide Covers This guide provides a complete, ready-to-use high-touch surface cle …Jan 16, 2026 -

Facility HVAC Cleaning Checklist: What to Clean, When, and Why

The Dust You Don't See In many facilities, floors get cleaned, windows shine, and restrooms are sani …Jan 09, 2026