Maintaining Your Commercial Floor Cleaning Machine: Essential Care Tips

A well-maintained floor-cleaning machine is crucial in today’s fast-paced industrial world. Various types of auto scrubbers require specific maintenance to ensure effective performance. Maintaining the brush head is essential for optimal performance, as it enhances dirt removal and contact with the floor. Proper maintenance can significantly impact operations, reducing downtime and ensuring smooth functionality. The statistics support this importance, as the global floor cleaning equipment market is projected to reach USD 27.56 billion by 2033, highlighting the value businesses place on these essential tools.

Industrial Floor Cleaning Equipment Maintenance

Why Proper Maintenance Matters for Productivity and Longevity

Good maintenance directly affects your bottom line by:

• Cutting down on surprise breakdowns and repair costs

• Making your equipment last longer

• Keeping cleaning quality consistent

• Helping maintain workplace safety standards

Overview of Common Types of Industrial Floor Cleaning Machines

The cleaning industry has come a long way, with specialized machines for every cleaning challenge. Here are the main types of equipment you’ll encounter:

• Commercial Floor Scrubbers: Perfect for giving smooth surfaces a deep clean, these machines are an effective investment for managing large commercial facilities. They enhance worker productivity, lower labor costs, and improve safety by reducing slip and fall hazards.

• Sweeper-Scrubbers: Great for bigger areas that need both sweeping and scrubbing

• Mechanized Mops: Handy for smaller areas and quick cleanups

• Robotic Floor Scrubbers: Self-operating machines for routine work

• Industrial Vacuum: Must-haves for any facility's daily upkeep

A wider cleaning path can significantly enhance productivity and efficiency by covering large areas more quickly, making it ideal for commercial environments.

Aligning Maintenance Practices with Business Needs

When planning your maintenance schedule, think about:

• When your facility operates

• What kind of dirt and debris you typically deal with

• What floor surfaces you have and how they need to be maintained

• What maintenance resources and expertise you have available

The key is making maintenance feel like a natural part of your operations while getting the most out of your equipment. This way, you're protecting your investment and keeping your workspace clean and safe.

Choosing the Right Industrial Floor Cleaning Machine

Choosing the right industrial floor cleaning machine can be a daunting task, especially with the numerous options available in the market. To make an informed decision, it’s essential to consider several factors, including the type of floor, the size of the area to be cleaned, and the level of cleaning required.

When selecting an industrial floor cleaning machine, consider the following:

• The Type of Floor: Different floors require different types of cleaning machines. For example, hard floors such as concrete, tile, and wood require a machine with a hard floor cleaning attachment, while carpets require a machine with a carpet cleaning attachment.

• The Size of the Area to be Cleaned: Larger areas require more powerful machines with larger cleaning paths, while smaller areas can be cleaned with smaller machines.

• The Level of Cleaning Required: If the floor requires deep cleaning, a machine with high cleaning power and advanced features such as scrubbing and sanitizing may be necessary.

Some popular types of industrial floor cleaning machines include:

• Floor Scrubbers: Perfect for cleaning hard floors, floor scrubbers come in various sizes and configurations, and are ideal for deep cleaning in both small and large spaces. A popular choice is MotorScrubbers M3M Floor Scrubber. Shop Floor Scrubbers to find the perfect option for your business!

• Floor Cleaners: Whether you need to clean carpets or hard floors, we offer versatile floor cleaners to tackle both surfaces. These machines are perfect for office buildings and commercial spaces that require efficient, everyday cleaning.

• Battery-Powered Floor Scrubbers: Need to clean areas without access to electricity? Our battery-powered floor scrubbers offer the flexibility to clean anywhere, without being tied to a power outlet. These machines are perfect for tight spaces and outdoor areas. Shop Battery-Powered Floor Scrubbers

By carefully considering these factors, you can select the right industrial floor cleaning machine that meets your specific needs and ensures efficient and effective cleaning.

Routine Maintenance Procedures for Key Equipment Types

Keeping a regular maintenance routine is key to getting the best from your industrial cleaning equipment. After years of working with various cleaning machines, I can tell you that good floor scrubber care makes a huge difference in how long your equipment lasts and how well it cleans.

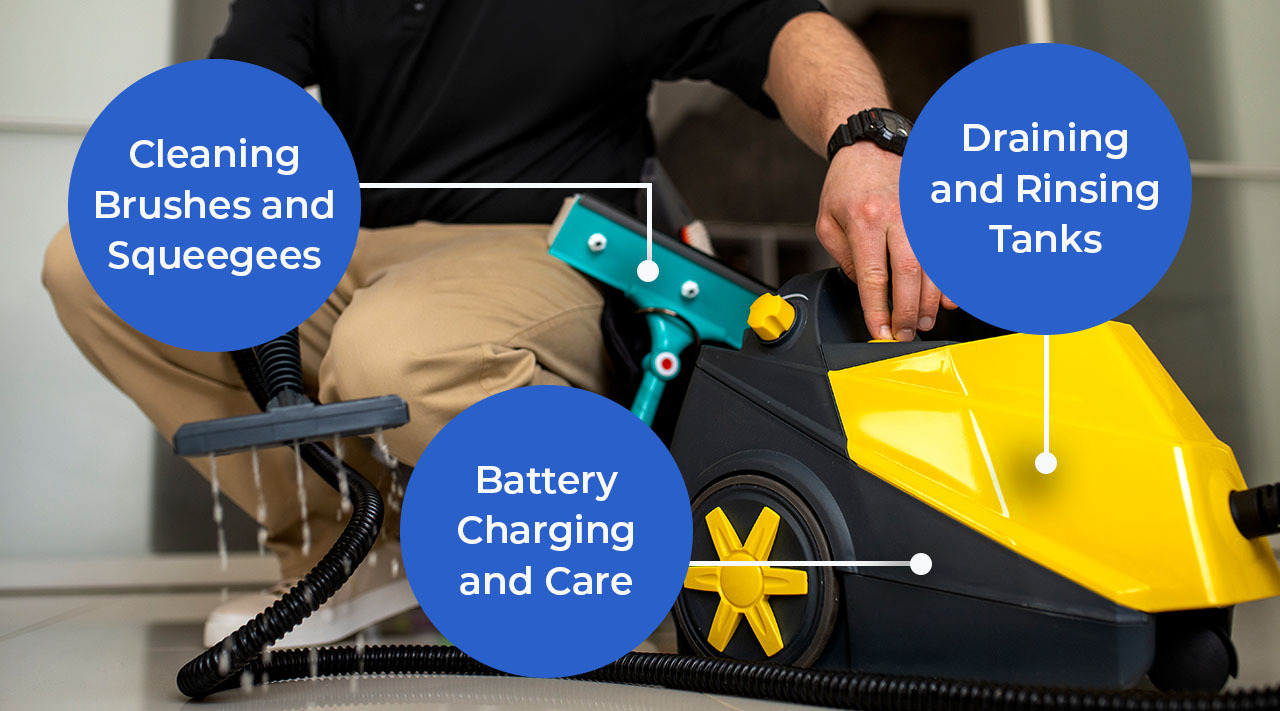

Daily Maintenance Checklist for Floor Scrubbers

Draining and Rinsing Tanks

One thing you absolutely can't skip is emptying and cleaning your solution and recovery tanks after each use. As my maintenance colleagues often say, this simple step prevents nasty odors and bacteria buildup while keeping your machine running smoothly. Here's what I do:

• Empty both tanks completely after use

• Give them a good rinse with clean water to get rid of any chemical residue

• Let them air dry when you can

• Keep an eye out for damage or leaks

Cleaning Brushes and Squeegees

Taking care of your brushes, squeegees, and pad driver is crucial for good cleaning results, as the pad driver plays a key role in attaching different cleaning pads. Additionally, maintaining the brush head is essential for optimal cleaning performance. A quick clean at the end of each day makes a world of difference. My daily routine includes:

• Getting rid of any debris stuck in brushes and squeegees

• Looking for signs of wear or damage

• Cleaning with the right solution

• Storing them properly so they keep their shape

Battery Charging and Care

Good battery care is essential. Here's what needs to happen:

• Charge batteries after every use

• Check water levels weekly if you're using wet batteries

• Keep battery connections clean and tight

• Make sure your charging area has good airflow

Maintaining Commercial Floor Scrubbers: Tips for Maximum Efficiency

For sweeper scrubbers, regular lubrication is super important. Machines without integrated traction rely on brush rotation to propel the machine forward, which can be labor-intensive for the operator. In contrast, those with an active traction motor facilitate smoother operation and reduce operator fatigue during lengthy cleaning sessions. You’ll want to:

• Clean out debris from brushes and hoppers daily

• Check sweep skirts and seals regularly

• Keep an eye on the brush pressure

• Make sure the vacuum fan is working well

Proper Care for Mechanized Mops

Mechanized mops need specific attention to keep working their best on hard surfaces, ensuring cleanliness and hygiene:

• Clean those mop heads thoroughly after use

• Keep the wheels clean and check them often

• Look over electrical parts for any damage

• Store in a dry place

Best Practices for Robotic Floor Scrubber Maintenance

Robotic scrubbers are pretty high-tech, but they still need regular care:

• Clean sensors every day

• Keep the software up to date

• Check and clean navigation cameras

• Monitor how the battery is performing

Vacuum Cleaners: What You Should Be Doing Weekly

For vacuums, weekly maintenance is crucial. A dirty filter can really hurt performance, so here’s my weekly checklist:

• Check and clean or replace filters

• Check and adjust belts

• Clean the brush roll

• Look for any blockages in the hoses

Advanced Maintenance Techniques for Prolonged Equipment Life

Let me share some advanced maintenance strategies I've picked up over the years. Going beyond basic daily care can make your equipment last longer and save you money in the long run.

Importance of Preventive Maintenance and Regular Inspections

I've found that having a solid inspection program makes all the difference. Here's how I break it down:

• Weekly: Quick checks of basic components

• Monthly: Overall performance reviews

• Quarterly: Deep dive into all systems

• Yearly: Professional inspection overhauls

When you're doing inspections, pay special attention to:

• How the motor's running and bearing condition

• Electrical system health

• Hydraulic pressure and fluid levels

• Drive train parts

• All safety features and emergency stops

Scheduled Servicing: When and What to Outsource

Knowing what to handle yourself versus when to call in the pros is crucial. Here's how I split it up:

Do it yourself:

• Basic fixes and adjustments

• Regular cleaning and lubrication

• Simple part swaps

• Battery maintenance

Call the professionals for:

• Major mechanical repairs

• Electrical system problems

• Hydraulic system work

• Software updates and calibration

• Annual full service

Utilizing Maintenance Software Solutions for Optimal Performance

Modern maintenance tracking tools can make a huge difference. I've seen equipment reliability improve dramatically when organizations use good maintenance software. These systems help you:

• Keep track of maintenance history

• Get automatic service reminders

• Watch equipment usage patterns

• Spot potential problems early

• Keep track of parts inventory

• Document repair steps

• Create performance reports

To get the most from your maintenance software:

• Make sure everyone's properly trained on how to use it

• Set clear rules for entering data

• Regularly check the reports it generates

• Use what you learn to improve maintenance schedules

• Connect it with your other business systems

Remember, the goal here is to catch and fix small issues before they become big problems. Being proactive about maintenance always pays off in the long run.

Safety Features and Precautions

Industrial floor cleaning machines can be hazardous if not used properly. To ensure safe operation, it’s essential to follow safety protocols and precautions.

Understanding Built-in Safety Mechanisms

Most industrial floor cleaning machines come with built-in safety mechanisms designed to protect both the operator and the equipment. These include:

• Emergency Stop Buttons: These buttons allow the operator to quickly stop the machine in case of an emergency, preventing accidents and damage.

• Safety Sensors: These sensors detect obstacles and prevent the machine from colliding with them, ensuring safe operation in busy environments.

• Warning Lights and Alarms: These lights and alarms alert the operator of potential hazards, such as low battery or clogged filters, allowing for timely intervention and maintenance.

Implementing Safety Protocols During Maintenance

Regular maintenance is essential to ensure the safe operation of industrial floor cleaning machines. Some safety protocols to implement during maintenance include:

• Wearing Protective Gear: Operators should wear protective gear, such as gloves and safety glasses when performing maintenance tasks to protect themselves from chemicals and debris.

• Following Manufacturer Instructions: Operators should follow the manufacturer’s instructions for maintenance and repair tasks to ensure they are performed correctly and safely.

• Testing the Machine: After maintenance, operators should test the machine to ensure it’s working properly and safely before returning it to service.

By understanding and implementing these safety features and protocols, you can ensure the safe and efficient operation of your industrial floor cleaning machines.

Troubleshooting and Overcoming Common Equipment Issues

After years in the field, I've run into pretty much every floor-cleaning equipment problem you can imagine. Let me share some real solutions that'll help you keep your machines running smoothly.

Addressing Ineffective Water Pickup

When your machine's not picking up water properly, it can be really frustrating. Here's my step-by-step approach to fixing it:

Check Squeegee Condition:

• Look for any tears or uneven wear patterns

• Make sure the tension's just right

• Double-check that the blade is installed correctly

• Clear out any debris that's gotten stuck

Look at the Vacuum System:

• Test if the vacuum motor is working properly

• Clear any blockages in the vacuum hose

• Check all vacuum gaskets

• Make sure the recovery tank seal is tight

Solving Insufficient Cleaning Results

When your cleaning results aren't what they should be, here's what I check:

Machine Settings:

• Check that the solution flow rate is correct

• Adjust brush or pad pressure

• Make sure speed settings are right

• Verify chemical mixing ratios

Equipment Parts:

• Look at the brush or pad condition

• Check how the solution is flowing

• Clean tank filters

• Monitor solution levels

Enhancing Battery Performance and Longevity

Battery issues can really slow you down. Here's how I keep batteries running strong:

Daily Care:

• Let batteries complete full charging cycles

• Check water levels in wet batteries

• Keep battery terminals clean

• Watch charging temperature

Long-term Care:

• Keep an eye on charging patterns

• Note battery age

• Do regular equalization charges

• Replace batteries when recommended

Quick Fixes for Unexpected Breakdowns

When something suddenly goes wrong, here's what I check first:

Emergency Checks:

• Look at circuit breakers

• Check all power connections

• Look for obvious damage

• Test emergency stop button

Basic Troubleshooting:

• Try resetting control systems

• Check fuses

• Test key switches

• Verify safety interlocks

Pro Tip: Keep these basics in your repair kit:

• Common fuses

• Basic tools

• Extra squeegee blades

• Emergency contact list

Remember, while you can fix many issues yourself, some problems need professional help. Don't hesitate to call in an expert for complex repairs.

Enhancing Equipment Lifespan Through Best Practices

After years in industrial floor maintenance, I've learned that getting the most life out of your equipment takes a complete approach. Let me share some strategies that have worked really well for my clients.

Selecting the Right Pads/Brushes and Cleaning Chemicals

Choosing the right tools and chemicals makes a huge difference. Here’s what I recommend:

For Pads:

• Use pad drivers to attach different types of pads, allowing for versatility in cleaning tasks.

• White - When you need to polish

• Red - For light, everyday cleaning

• Blue/green - When you need to scrub harder

• Black - For stripping floors

For Chemicals:

• Always match the pH to your cleaning needs

• Never mix different cleaning products

• Follow mixing instructions carefully

• Consider eco-friendly options when possible

Environmental Factors: Storage and Usage Considerations

Where and how you store your equipment really matters. Here's what works best:

Storage Needs:

• Keep in a temperature-controlled area if you can

• Avoid extreme hot or cold

• Store in a clean, dry space

• Make sure there's good air flow

• Keep it easily accessible for maintenance

Usage Tips:

• Don't use in extreme temperatures

• Keep equipment out of rain and moisture

• Stay away from harsh chemicals

• Make sure work areas have good ventilation

Training Staff on Effective Operational Techniques

Operations:

• The right way to start up machines

• How to handle equipment properly

• Managing speed and pressure

• What to do in emergencies

Maintenance:

• Daily inspection routines

• Basic troubleshooting steps

• Proper cleaning methods

• How to keep good records

Partnership with Professional Service Providers for Enhanced Support

Having a good relationship with service providers is super important. It's also crucial to adhere to specific in-house best practices for maintaining cleanliness.

Look for:

• Partnership Benefits:

• Regular maintenance scheduling

• Quick emergency repairs

• Access to technical experts

• Easy parts availability

• Ongoing training support

What to Look for in Service Agreements:

• Guaranteed response times

• Preventive maintenance plans

• Cost-effective service packages

• Available technical support

• Training programs

Tips for Working with Service Providers:

• Keep detailed service records

• Schedule regular maintenance

• Report problems right away

• Follow manufacturer guidelines

• Keep all equipment documents organized

Remember, these practices aren’t just about maintenance - they’re about protecting your investment and making sure your cleaning stays consistent. Pay attention to these details, and your equipment will serve you well for years.

Compliance and Regulatory Considerations

Industrial floor cleaning machines must comply with industry standards and regulations to ensure safe operation and minimize environmental impact. Compliance with these standards not only ensures the safety of operators but also helps in maintaining the longevity and efficiency of the equipment.

Conclusion and Key Takeaways

After spending years in the industrial floor maintenance world, I can tell you that taking care of your equipment isn't just about following a manual -it's about understanding what works in real-world situations.

Summarizing the Importance of Regular and Thorough Maintenance

I've seen firsthand how good maintenance can transform equipment performance. The benefits are clear:

• Your equipment lasts way longer

• You deal with fewer surprise breakdowns

• You spend less on repairs

• Your cleaning results stay consistent

• Your workplace stays safer

Here's something I've learned: every dollar you spend on preventing problems saves you about three or four dollars in emergency fixes later on.

Encouragement to Create a Maintenance Schedule Tailored to Your Equipment

Creating a maintenance schedule doesn't have to be complicated. Start with:

Daily Tasks:

• Basic cleaning after use

• Quick visual checks

• Battery care

• Empty and clean tanks

Weekly Jobs:

• More thorough cleaning

• Check all parts

• Test how everything's working

• Check your supplies

Monthly Tasks:

• Detailed inspections

• Preventive maintenance work

• Update your records

• Refresh staff training

Final Tips for Maximizing Your Equipment Investment

Here's what I've found works best for getting the most from your cleaning equipment:

Focus on Training:

• Make sure everyone knows how to use the equipment properly

• Run regular refresher sessions

• Write down what works best

• Listen to operator feedback

Stay Ahead of Problems:

• Fix small issues before they become big ones

• Keep good maintenance records

• Keep spare parts on hand

• Build good relationships with your service providers

Think Long-term:

• Consider the total cost of ownership

• Plan for future upgrades

• Set aside money for maintenance

• Track how your equipment performs

Remember, good maintenance isn't just about following checklists - it's about creating a culture where everyone understands the value of taking care of the equipment. When you do this right, you'll see better performance, less downtime, and equipment that lasts longer.

Your cleaning equipment is a serious investment in your facility's success - treat it that way, and it'll keep delivering value year after year.

Frequently Asked Questions (FAQ)

What are industrial floor cleaning machines?

Industrial floor cleaning machines are specialized equipment designed to clean large commercial and industrial spaces efficiently. They include various types such as floor scrubbers, sweepers, and vacuum cleaners, each suited for different cleaning needs and surfaces.

How often should I perform maintenance on my floor cleaning machines?

Regular maintenance is crucial for optimal performance and longevity. Daily tasks include cleaning tanks and checking brushes, while weekly and monthly checks involve more thorough inspections and preventive maintenance. Always refer to the manufacturer's guidelines for specific maintenance schedules.

Can I use the same cleaning machine for both carpets and hard floors?

Some floor cleaners are versatile and designed to handle both carpets and hard floors. However, it's essential to ensure the machine has the appropriate attachments and settings for each surface type to achieve the best cleaning results.

What safety features should I look for in commercial floor machines?

Key safety features include emergency stop buttons, safety sensors, and warning lights or alarms. These mechanisms help prevent accidents and ensure safe operation in busy environments.

Are there eco-friendly options for cleaning chemicals used in floor scrubbers?

Yes, many manufacturers offer eco-friendly cleaning solutions that are effective and environmentally safe. Always ensure the chemicals are compatible with your equipment and suitable for the surfaces you are cleaning.

By addressing these common questions, we hope to provide clarity and assist you in making informed decisions about your industrial floor cleaning equipment

Recent Posts

-

High-Touch Surface Cleaning Checklist & Guide for Facilities

Overview: What This Guide Covers This guide provides a complete, ready-to-use high-touch surface cle …Jan 16, 2026 -

Facility HVAC Cleaning Checklist: What to Clean, When, and Why

The Dust You Don't See In many facilities, floors get cleaned, windows shine, and restrooms are sani …Jan 09, 2026 -

Fragrance-Free vs Scented: Build an Allergy-Safe Cleaning Program that Still Works

When "Clean" Becomes a Complaint You know the scene: your custodial team disinfects the office overn …Dec 05, 2025